In the field of clothing, there are many ways of printing, different printing process on the printed pattern effect will be different, the following I will introduce several printing process commonly used in today’s clothing fabric processing.

1. Screen printing

Screen printing is the most common printing process in T-shirt printing, has a long history, suitable for mass printing the same type of pattern clothes, and no requirements for the color and material of clothes, traditional screen printing according to the printing effect and process can be divided into: water paste printing, paste printing, ink printing, dyeing printing, foam printing, hot stamping, flocking, etc.. Garment factories will add some special materials in the dye according to customer needs to produce different printing effects, but screen printing can not print gradient colors, screen printing in the need to produce printing plates, so the cost is relatively high, not suitable for small quantities of custom clothing.

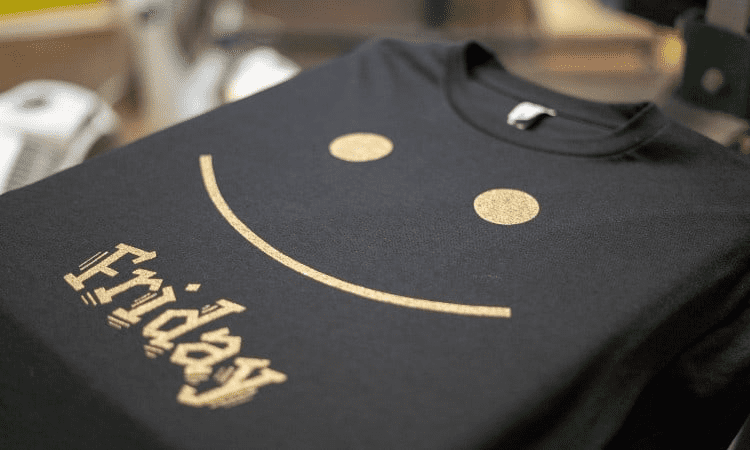

2. Heat transfer printing

Heat transfer printing is the first printed pattern printed on the heat transfer paper, and then through the machine generated by high temperature and pressure to transfer the pattern to the clothes, this printing process is relatively simple, and the finished pattern is delicate, layered, very suitable for small batch of clothing customization, can be under the sun for a long time, there will be no deformation, discoloration, there is a very rich color expression, can do character pictures, small text It can be used for high-definition and complex patterns such as characters, small text, letters, and corporate logos. However, this process is mainly applicable to clothing with chemical fiber as the main raw material, not for fabrics containing more cotton or other components, and only for light-colored clothing.

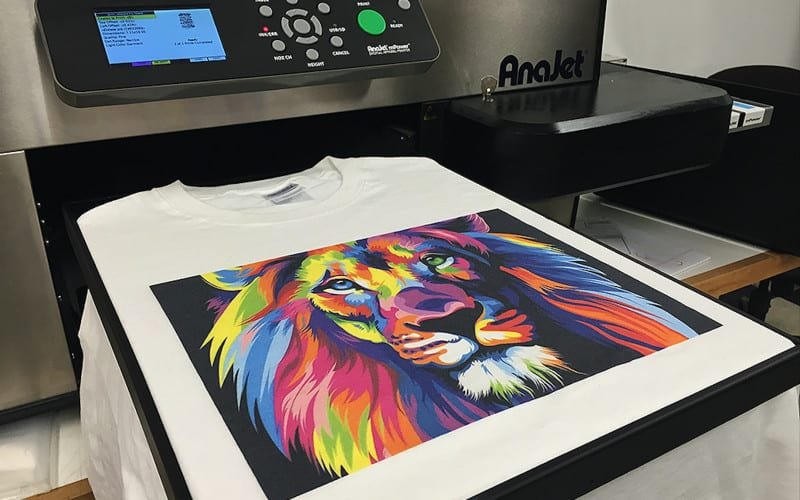

3. Digital direct-jet printing

Digital direct-jet printing is designed by computer, and then through the digital direct-jet printing machine will be ink directly printed on the garment, its biggest advantage is that the operation is convenient and fast, and suitable for most of the clothing fabrics on the market, it can spray more complex gradient color pattern, color fastness can reach more than 4 levels without fading or bursting, and the pattern is flexible, generally some support for personalized customization services of clothing businesses like to use this printing method.

4. Embroidery

Embroidery is one of China’s excellent national traditional crafts, which is a process of using various colored threads such as silk, velvet, cotton, etc. to form various beautiful images, patterns or words on materials such as silk, cloth and modern chemical fiber fabrics with the up-and-down piercing movement of a tiny steel needle. With the addition of embroidery, contemporary clothing has become more and more popular among consumers because of its high ornamental and artistic value.

Machine embroidery is widely used for mass production of garments because of its speed, but the effect of machine embroidery lacks a sense of hierarchy and is rather rigid. Hand embroidery is usually used for custom-made garments or garment crafts. Hand embroidery requires high manual skills and takes several weeks to complete a garment, so it is more expensive, but the hand embroidered patterns are vivid and colorful and have high collection value.

These are some of the more common printing processes used in garment production. Of course, with the advancement of technology, there are more and more garment printing processes, and garment manufacturers will use different printing methods according to different production needs.